Surface treatment

Surface treatment, 3D UV varnishing and 3D preg foiling

Make your products stand out from the crowd, choose Center-Print surface finishing and UV varnishing solutions! Contact us today, we will find the best possible solution for you together!

UV varnishing, surface finishing with the Center-Print team – that’s why you choose us!

The key to standing out in today’s saturated market is quality and uniqueness. You are guaranteed a premium service from our professional printing team, which gives you a competitive advantage. Let’s see how we really differ!

Unique, creative and effective surface finishing solutions

Our latest investment is an MGI JETVARNISH 3D ONE type machine, which opens completely new perspectives in the world of varnishing and stamping!

3D UV varnishing and preg foiling is an innovative technology that gives a beautiful 3D effect and makes your products unique!

We still use traditional surface finishing processes in our work today, but our MGI Jetvarnish machine has raised the potential of surface finishing to a new level.

Another great advantage of this digital technology is the time and cost efficiency, as this process can replace traditional embossing and there is no need for clichés or sieves during production. Its use is profitable even in the case of a small number of copies.

Let you have any kind of need, we are at your disposal with customized solutions.

Flexible, customer-oriented business model

Quick quotation, maximum flexibility and customer focus – these are the basic principles of Center-Print.

Our goal is to make the customer’s satisfaction – and the efficiency of the work – the priority during every project.

Quality above all else

We demand the highest quality expectations from ourselves in each and every one of our jobs.

Quantity is no obstacle either

If you would like to order in large batches, this is not an obstacle for us either, in fact, we are specially prepared to handle larger volume projects as well. Of course, this is not impact the quality, quick quotation and creativity.

Meaning of UV varnishing and surface treatment

UV varnishing and surface finishing are processes that improve printed materials not only aesthetically, but also in terms of their durability. During UV varnishing, a special varnish is applied to the surface, which dries under the influence of UV light. As a result, the surface becomes brighter and more resistant to scratches and wear.

Surface finishing includes various techniques such as embossing and lamination, all of which contribute to making the final product unique and durable. These processes raise the printed materials to a higher level not only in their appearance, but also in their functionality, ensuring their longevity and outstanding quality.

Other surface treatment processes, 3D UV varnishing

We offer a wide range of surface finishing processes, which include the aforementioned embossing, various varnishing and laminating techniques, such as 3D UV technology, which is implemented with our latest machine, the MGI JET Varnish 3D.

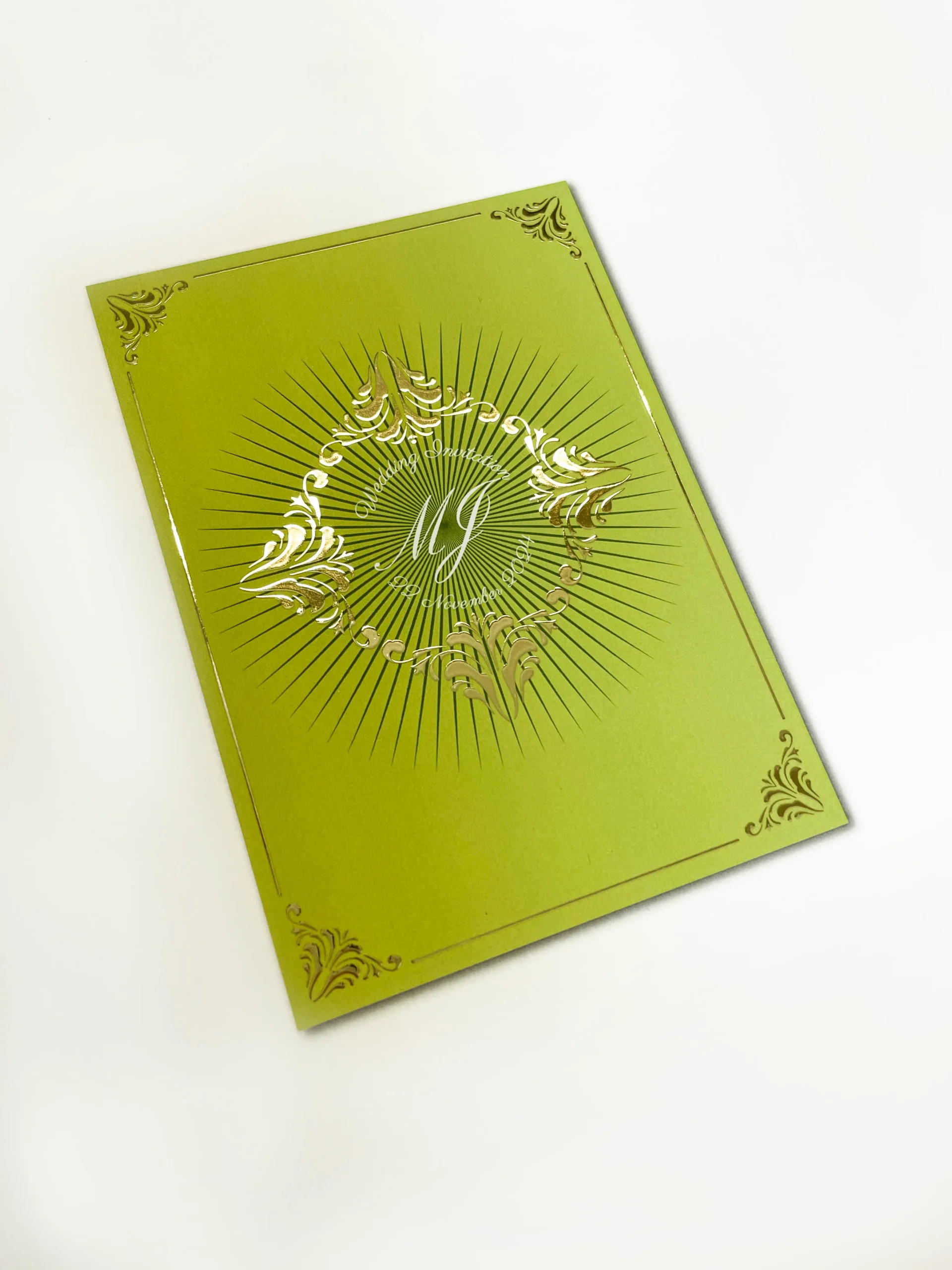

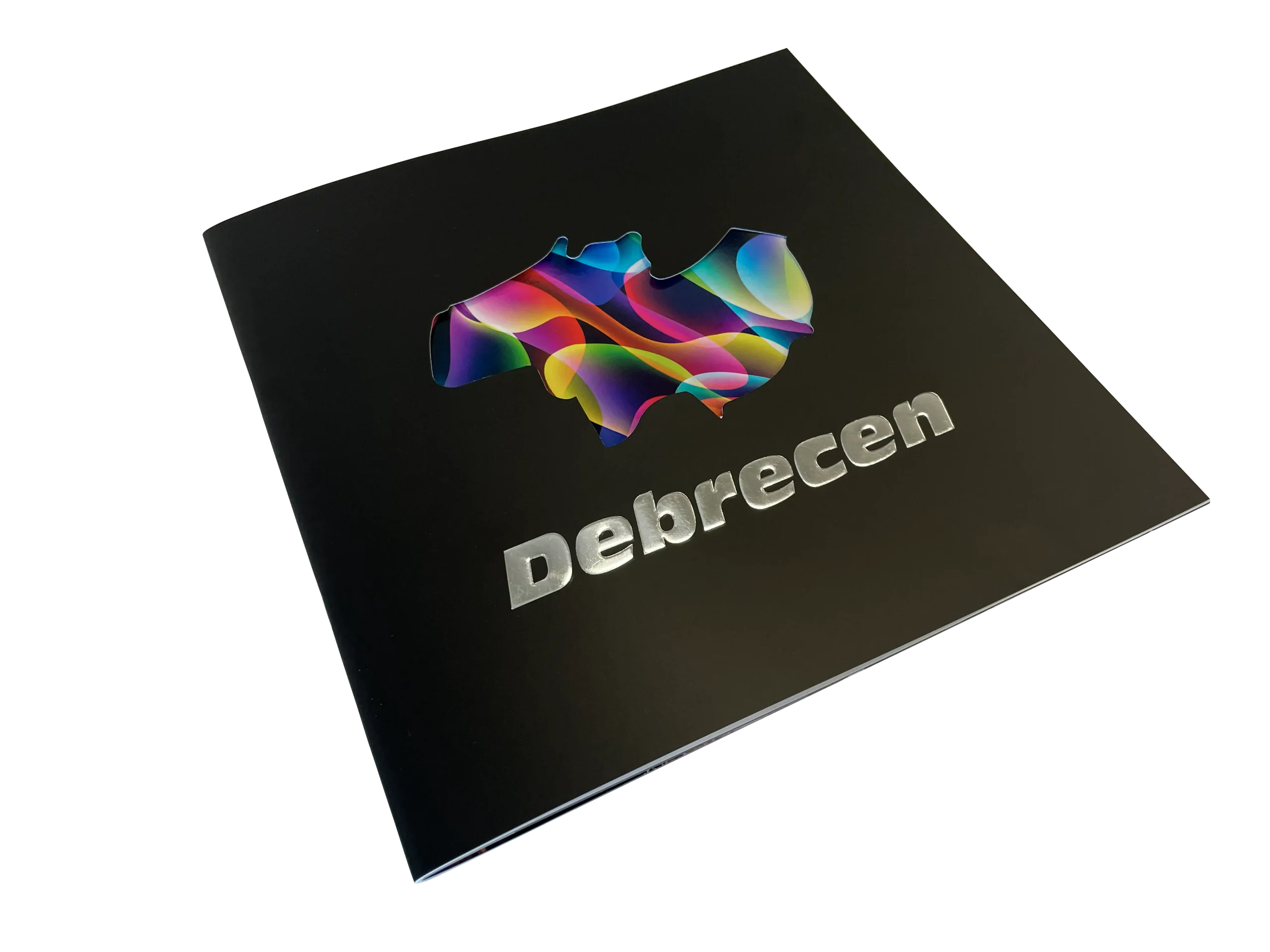

Embossing is an elegant solution when the printed surface is embossed, so that the pattern or text stands out from the paper, providing a special tactile and visual experience.

With the help of 3D embossing, we can achieve a 3D effect on the products, and it is even perfectly suitable for emphasizing one area.

Embossing can be done in gold, silver or red.

3D UV varnishing is available in many forms, including matt, glossy or even structured varnishes, all of which provide a unique look. During lamination, a protective layer is placed on the printed surface, which increases its lifespan and provides protection against moisture, dirt and other harmful effects.

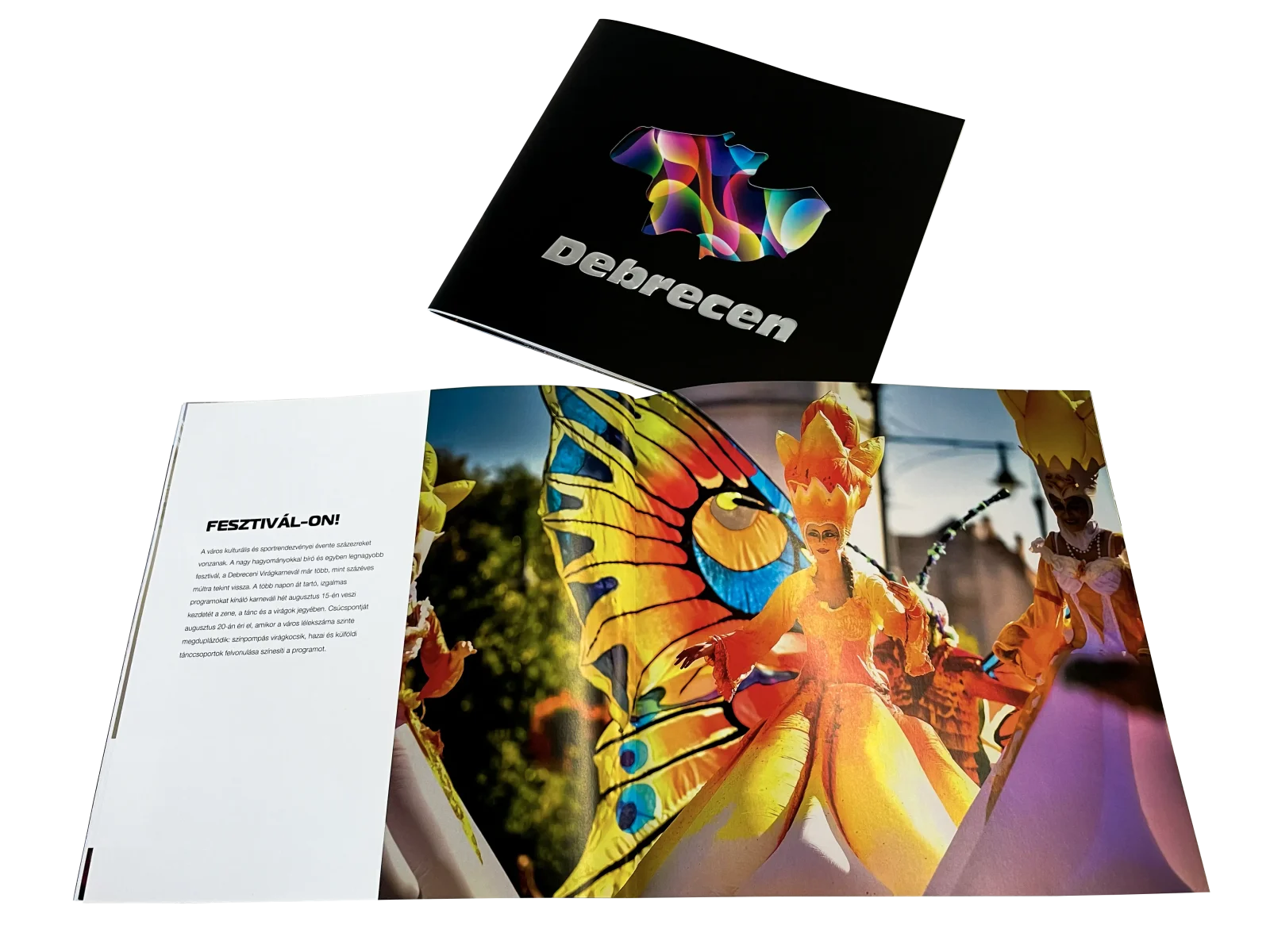

With the 3D UV varnishing technology, we can achieve even more brilliant film effects in both digital and offset printing. With our MGI JETvarnish 3D machine, we give prints a new and unique look. With this special surface treatment technique, you can become unique on the market, because the products will be immediately noticeable with their spectacular, bright colors and tactility.

Since UV and 3D UV varnishing is an extremely versatile technology, it can be used for both offset and digital printing.

It is also a popular alternative for offset printing because it can be used perfectly for high-quality printed materials with a large number of copies. The varnish dries quickly under the influence of UV light, so the printed products are immediately ready for further processing or shipping. With the 3D foiling process, you can offer creative printed products to your customers, thus ensuring market competitiveness.

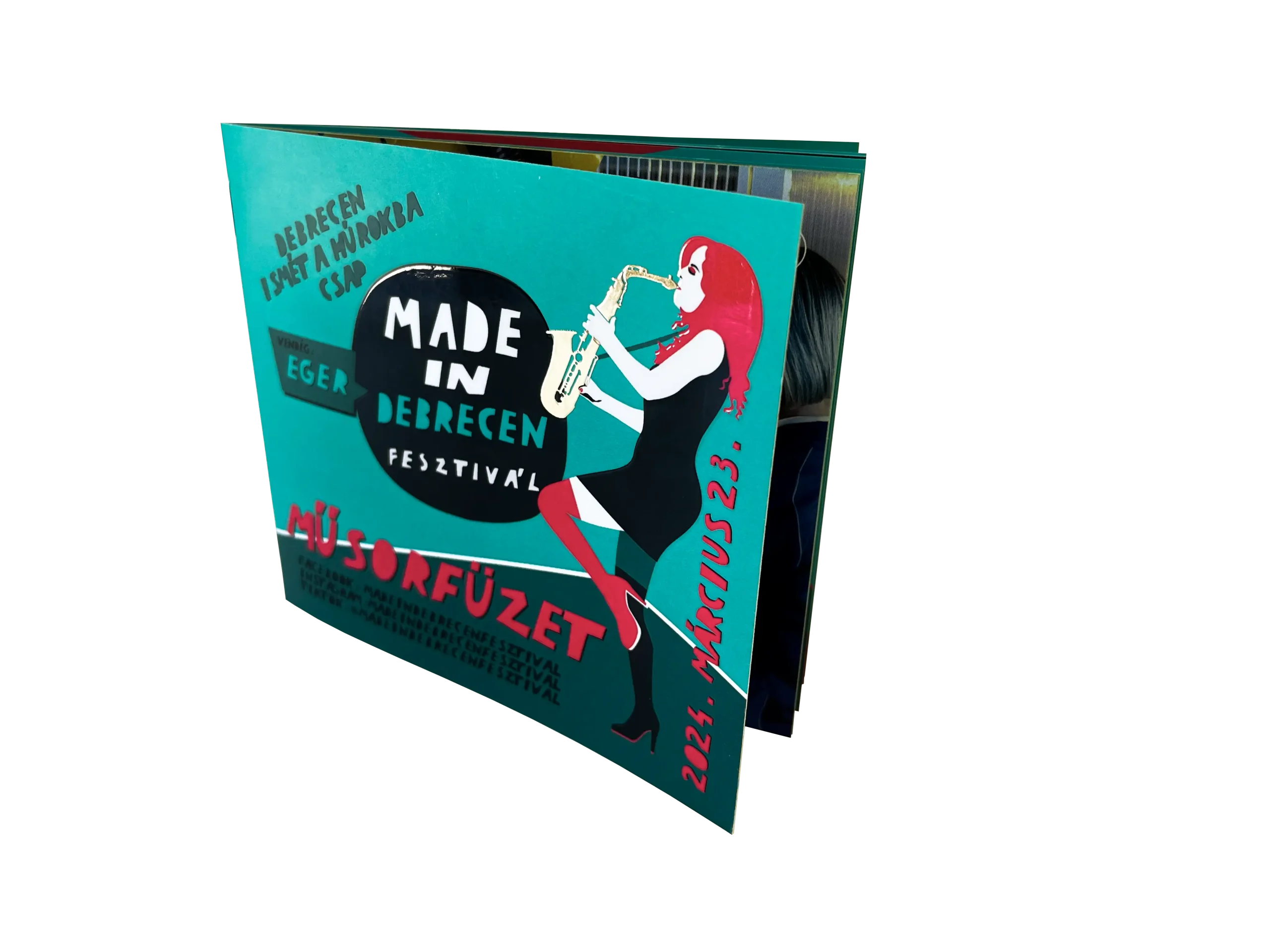

In the case of digital printing, UV varnishing offers the opportunity to create smaller, unique prints that are just as durable and aesthetically attractive as products made with offset printing. Whether it’s brochures, business cards, book covers or any other printed material, 3D UV digital varnishing is guaranteed to increase visual impact and durability. With this method, ordinary prints instantly become brilliant and revolutionary.

Advantages

- It is also a good solution for small quantities. Graphics can be easily modified or enhanced thanks to digital technology.

Disatvantages

- Open-structured, offset-type paper cannot be used to create a 3D effect and for UV form varnishing, as the varnish can easily penetrate the paper.

- The surface of the preg foil can be damaged more easily, as it protrudes minimally from the surface.

If you need unique, creative solutions, or if you want to order a larger quantity, you’ve come to the right place. Our goal is to provide our customers with the highest quality service, helping them to stand out from their competitors.

Which products for do we recommend the surface treatment technology?

- exclusive packaging

- beverage and food packaging

- cosmetic packaging

- accident forms

- business card

- for rendering special material patterns, textures and effects

- for highlighting and contouring any graphic element

Gallery

Have we sparked your interest?